Lightweight and high-strength semi-finished products for tapping maximum lightweight construction potential

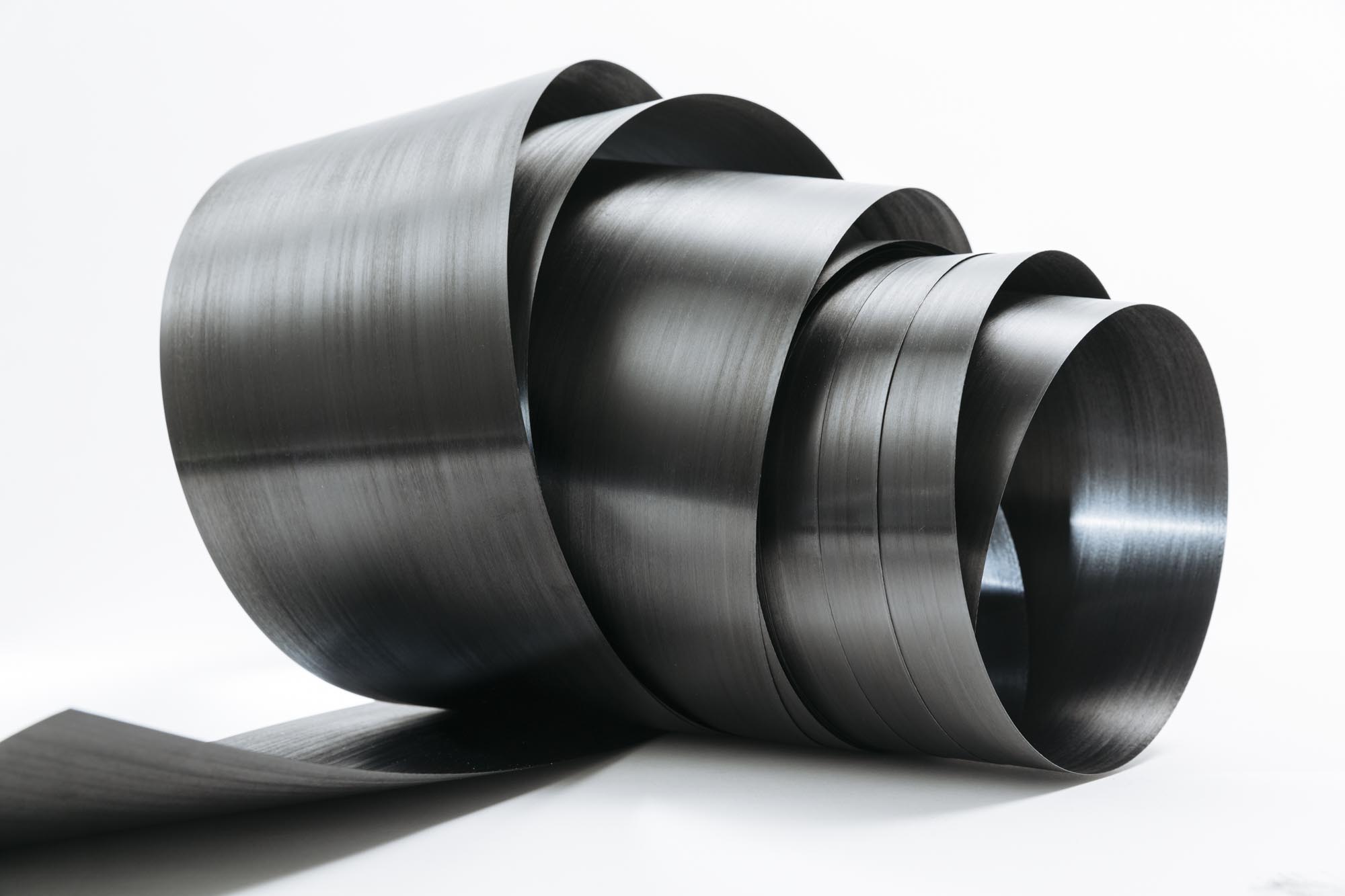

Unidirectional tapes, also known as UD tapes, are continuous fiber-reinforced tapes of different widths with unidirectionally aligned reinforcing fibers.

Fiber composites made from unidirectional continuous fiber-reinforced thermoplastic semi-finished products in the form of tapes or profiles offer optimum lightweight performance and material efficiency in the production of complex and high-strength structural elements. Unidirectional continuous fiber reinforcement can be used for a variety of applications, e.g. in the form of load-path-compatible cover layers for honeycomb or foam cores or in the form of solid rods or semi-finished profiles with integrated fiber reinforcement.

Thanks to its modular design, cost-efficient direct melt impregnation offers unique potential for a wide range of material compositions and manufacturable semi-finished product geometries. Functionalized tapes, e.g. with flame-retardant properties, can also be produced.

The melt impregnation systems at the Fraunhofer Institute for Microstructure of Materials and Systems IMWS are specifically designed for development and scale-up to pilot scale and enable direct transfer to large-scale production.

The advantages of melt impregnation at a glance:

- Direct processing of the raw materials into semi-finished UD products without additional working steps

- Modular wetting nozzles allow the use of a wide range of thermoplastics from standard plastics to high-temperature plastics or functionalized compounds for special applications

- High material efficiency in combination with the lowest possible thermal stress on the matrix polymers

- High fiber content possible (e.g. glass fibers of up to 80 w% or 60 v% )

The Fraunhofer-IMWS has many years of experience in the field of application-specific material development and technical process development for the production of UD tapes. This know-how is complemented by a comprehensive range of quality assessment services (non-destructive and destructive) as well as the possibilities for further processing of the tapes , e.g. in hybrid injection molding processes or tape-based 3D printing processes.

Material development for application-specific UD tapes:

- Matrix materials: PE, PP, PA, PET, PC, PPA, biopolymers, others

- Fiber materials: GF, CF, basalt, polymer fibers, bio-based fibers, others

- Adjustment of performance properties

- Customized material development

- In-process testing technology and inline testing methods

- Material sampling

Material sampling

Life cycle assessment and evaluation of recyclability in relation to application

We are your contact for the development, pilot-scale production and further processing of UD tapes and their evaluation.