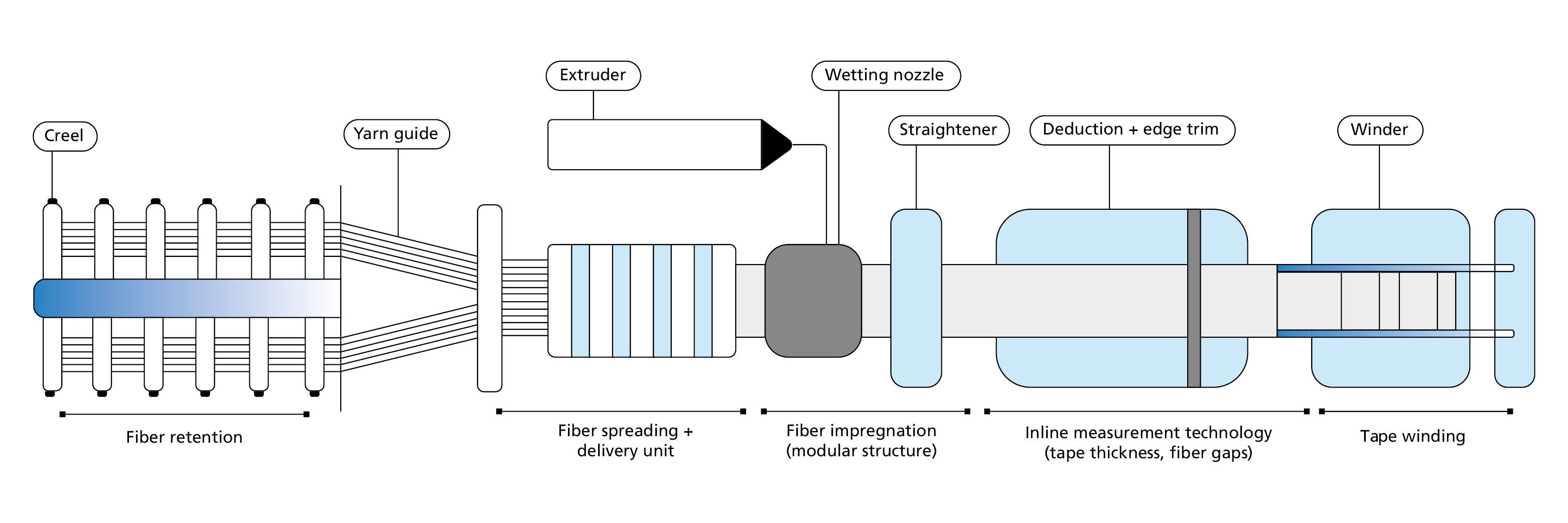

Melt impregnation technology

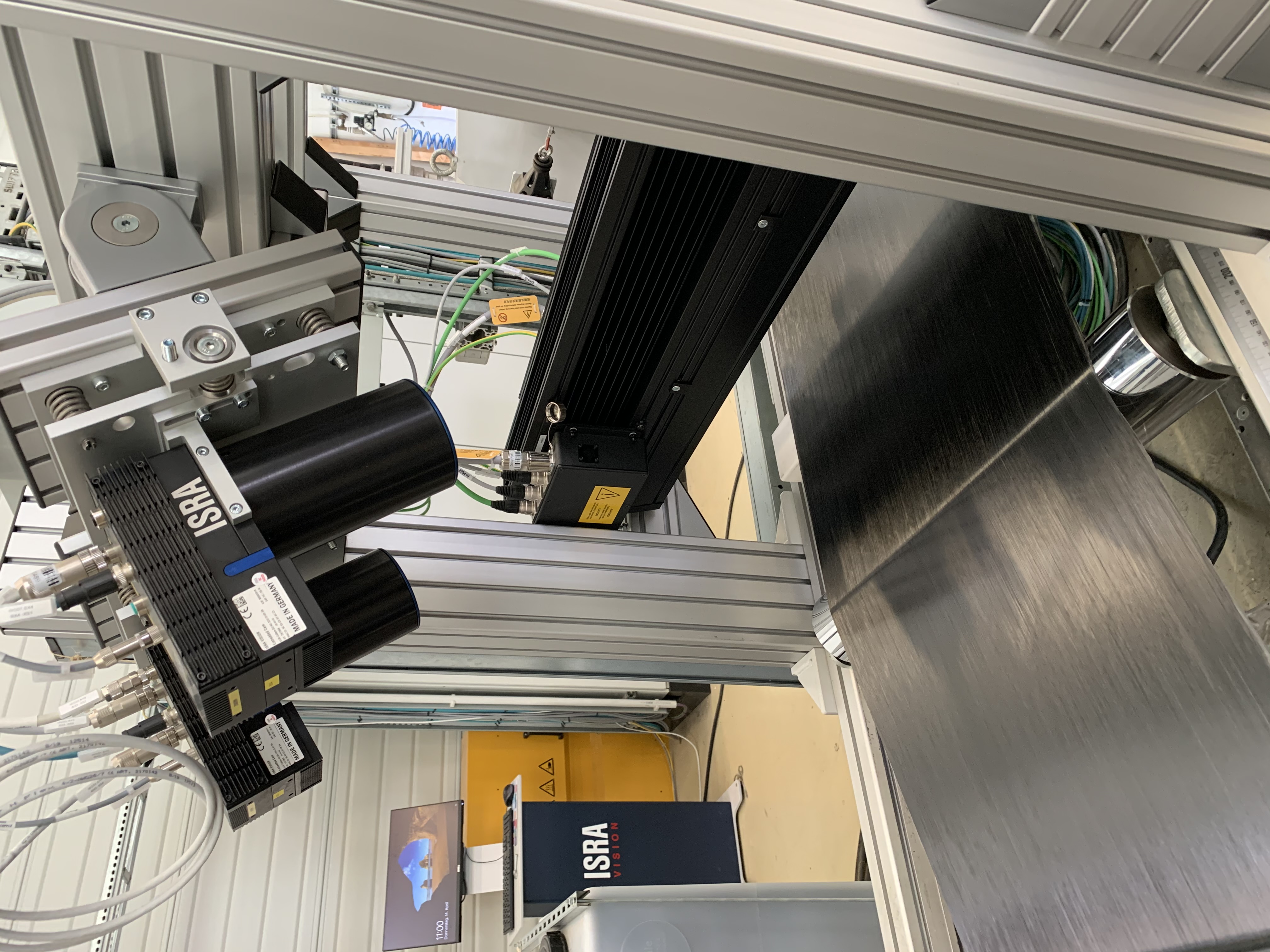

Meltimpregnation is based on the infiltration of unidirectionally oriented reinforcing fibers using plasticized thermoplastic polymers. To do this, it is first necessary to align and spread the required fiber rovings. Downstream the fibers are impregnated with matrix in the wetting nozzle. After passing through the nozzle, the semi-finished products are cooled using a two-roll calender (smoothing unit) and molded close to the final contour. The edges are trimmed and the semi-finished products are assembled on winding cores.