Photovoltaic test station brings the desert into the laboratory: Klemens Ilse from Fraunhofer CSP wins award

Morocco, Saudi Arabia, Dubai: New solar parks are currently being created in many desert regions. However, the soiling of the photovoltaic modules with sand and dust presents a challenge. At the Fraunhofer Center for Silicon Photovoltaics CSP, a technique has now been developed in collaboration with partners, allowing this soiling behavior to be simulated in the laboratory – an important prerequisite for being able to optimize the materials used and thus also the yield. Klemens Ilse from Fraunhofer CSP received the Best Student Paper Award for this from the expert conference IEEE PVSC 44.

The use of photovoltaics in desert regions offers many advantages: at the equatorial sun belt of the Earth, insolation is sometimes twice as high as at our latitude, and there are no conflicts concerning the use of land: the land used for new solar parks is not suitable for residential use or for agriculture. However, solar modules must also fulfill special requirements when operated in desert regions. Besides UV radiation and the great temperature differences between day and night, these requirements include the soiling of the modules: when the desert wind blows dust and sand onto the system and this then becomes “baked” onto the surface of the modules when dew forms, less light reaches the solar cells, resulting in less electricity being produced.

»Soiled modules are currently primarily cleaned mechanically, such as by wiping, with a broom or with cleaning robots. A better solution would be to have optimized surfaces on the modules, which ensure that dust and sand cannot adhere as strongly and natural cleaning mechanisms such as the wind can achieve a better effect. We want to help develop the right materials for this,« says Klemens Ilse, who is currently working on his doctoral thesis on the soiling of solar modules in desert regions at Fraunhofer CSP.

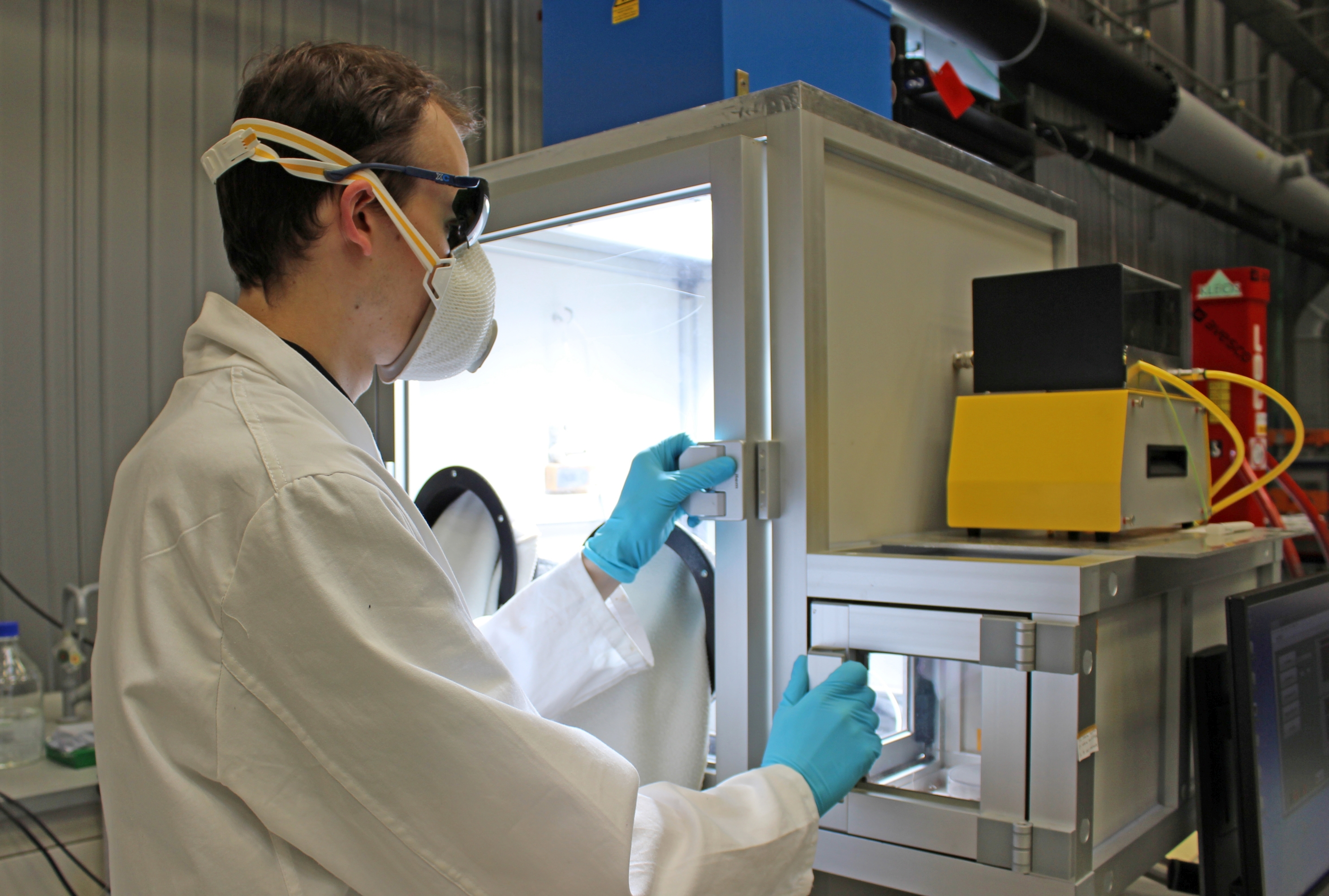

This requires a precise understanding of the soiling behavior. What composition, size distribution and structure do the dust and sand particles have? How do they react with the glass used to cover the solar modules? How does this process change when moisture – such as morning dew – comes into play? To investigate these questions, a soiling test station was built at Fraunhofer CSP in cooperation with Anhalt University of Applied Sciences. “This allows us to realistically simulate both the dusting behavior of coated glass samples and the dewing processes in the laboratory,” explains the 27-year-old physics doctoral candidate.

Ilse showed how well the simulation works in the laboratory in his essay ‘Comparing indoor and outdoor soiling experiments for different glass coatings and microstructural analysis of particle caking processes,’ for which he was honored with the Best Student Paper Award as part of the IEEE Photovoltaic Specialists Conference (PVSC) 44 in Washington. His results show: The data from the laboratory correspond well with the data measured during a five-month comparison test in the Atacama Desert in Chile. The key advantage here: Instead of several months, just a few hours were needed in the laboratory to obtain the desired results using soiling patterns or the establishment of dust layers. This accelerates the development of optimized glass to cover the top of solar modules.

Microstructural examinations of dust-covered glass samples from Chile at Fraunhofer CSP have also shown that various processes lie behind the adhesion of particles: The samples from Chile do not show cementation (the attachment of the particles due to the precipitation of salts previously dissolved in water droplets), but rather »particle caking«. The Fraunhofer researchers use this term to describe a process in which the attachment of larger particles occurs due to the rearrangement and compaction of very small particles (less than 4 micrometers) during dew-forming processes. Plate-shaped clay minerals such as kaolinite fill the gaps between larger particles and the glass surface. This results in a larger contact area, and greater adhesive forces are also created for the large particles – the dirt thus adheres even more strongly to the glass surface.

As the increasing demand for photovoltaic solutions for desert regions requires uniform standards for dust tests, the Association of German Engineers VDI and the German Institute for Standardization DIN have recently founded a standardization committee led by Klemens Ilse. Based on the recommendations of this committee, Topas GmbH, based in Dresden, plans to develop a test station and bring the product onto the market in 2018.