New method for defect diagnosis in PEM and AEM electrolyzers

How can microstructural defects that affect the overall performance of an electrolyzer be located non-destructively? Until now, this has been difficult as common methods are non-imagining. Here the "VACE-LIT" method developed by the Fraunhofer Institute for Microstructure of Materials IMWS offers a solution.

Hydrogen technologies are seen as a promising key element for a successful energy transition. One technology for the production of low-carbon hydrogen is electrolysis, where hydrogen is produced by splitting water using electricity. There are different methods for this process. The most common ones currently include alkaline and high-temperature electrolysis, as well as membrane-based "proton exchange membrane", or PEM electrolysis, and "anion exchange membrane", or AEM electrolysis.

To efficiently convert electrical into chemical energy, the current density in the PEM or AEM electrolysis cells must be evenly distributed. Defects and changes in the material can affect energy efficiency and performance. Therefore, performance and load tests are conducted during the development of materials, components and cells. Until now electrochemical impedance spectroscopy and polarization curve measurements are commonly used for defect diagnosis. However, as these methods are inherently non-imaging, lateral inhomogeneities and local degradations or defects cannot be mapped and thus localized

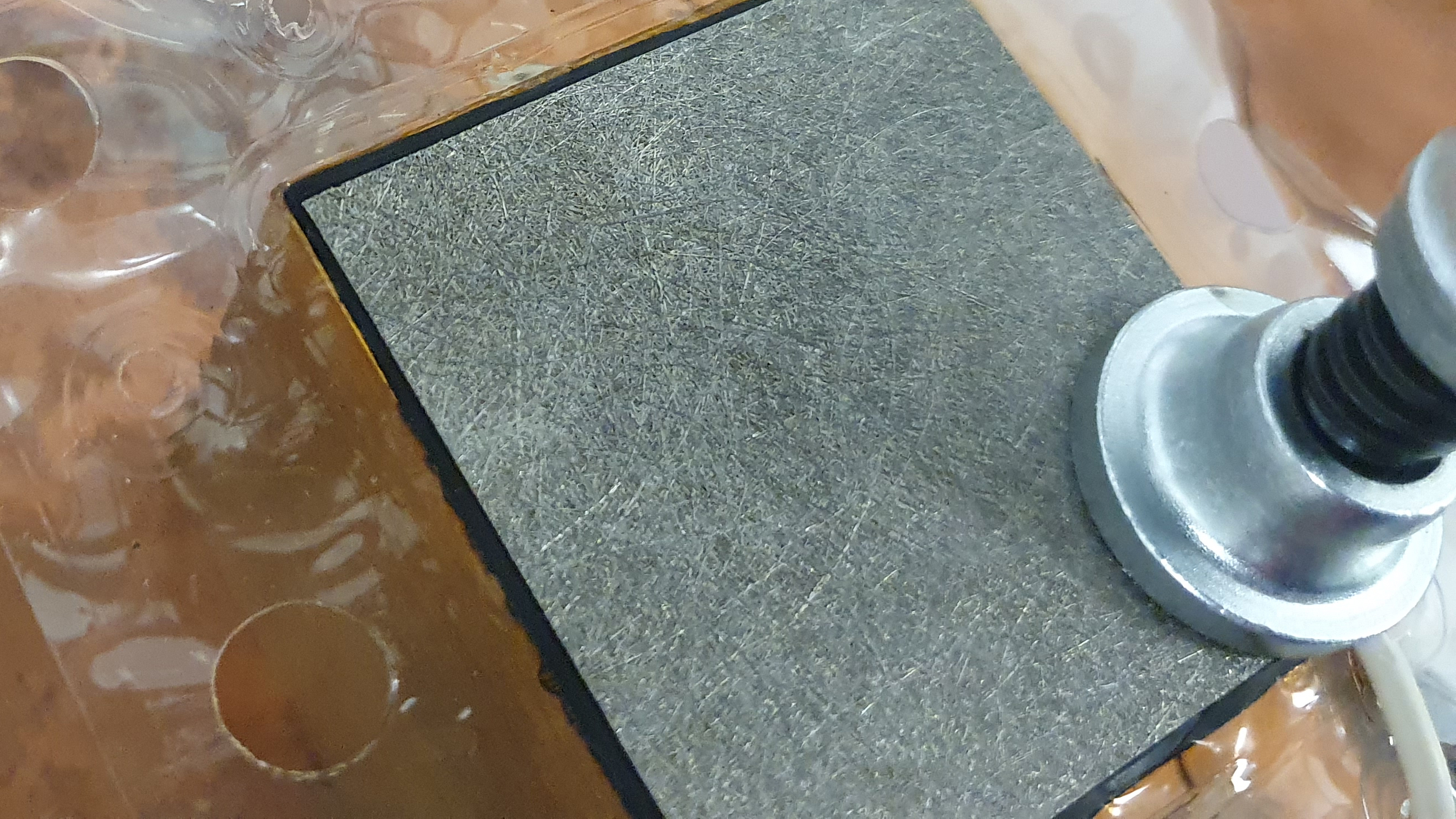

A method has now been developed at the Fraunhofer IMWS that makes it possible to map current flows and electrical losses. This new "Variable-Frequency AC Excitation Lock-in Thermography", or "VACE-LIT" method, combines aspects of electrochemical impedance spectroscopy with lock-in thermography (LIT) and is applied to a PEM electrolysis membrane electrode assembly (MEA). Lock-in thermography allows sensitive imaging of current flows and electrical losses within a MEA with high resolution . With conventional LIT, defects can be diagnosed using short intermittent direct currents (pulsed direct current), which periodically generates heat in the object under investigation, and a camera that is highly sensitive in the mid-infrared wavelength range. The problem, however, is that conventional LIT using pulsed direct current does not work without simultaneous water electrolysis.

The innovative idea of the "VACE-LIT" method is the use of pulsed alternating current. It has shown that PEMs can exhibit highly inhomogeneous current densities, presumably due to contact resistances in the layer stack. Furthermore, local currents flowing at low frequencies indicate electronically conducting defects in the membrane.

"VACE-LIT" is a non-destructive method for the diagnosis of electrical inhomogeneities and defects in polymer electrolyte membrane electrode assemblies, as used in water electrolyzers and similarly in fuel cells. The newly developed method enables the localization of defects down to the micrometer scale and is therefore suitable for locating defects already at cell level. "It is not yet commonly known which types of microstructural defects evolve in the long-term operation of full-size PEM and AEM devices, and which of these defects have the severest negative impact on performance and efficiency. However, the "VACE-LIT" method we have developed is predestined for the initial detection and localization of cell-level defect sites, which stands at the beginning of any microstructural defect elucidation", says Volker Naumann, Team Leader "Defect Diagnostics", Group "Materials Diagnostics for H2 Technologies" at Fraunhofer IMWS.

The "VACE-LIT" method is thus an essential building block for rapid and target-oriented microstructural defect diagnosis, which, in turn, can increase the overall efficiency and service life of PEM and AEM electrolyzers as well as fuel cells at significantly reduced development effort.