Software tools as a starting point for new methods to reduce tyre wear

Microplastics are found almost everywhere in nature. A study prepared as part of the mFUND program of the Federal Ministry of Digital Affairs and Transport states that the most common source of microplastic particles in the environment is the abrasion of car tires. How can the inline measurement of tire abrasion be used to find ways to reduce microparticle emissions? This question is being investigated by the Fraunhofer Institute for Microstructure of Materials and Systems (IMWS) and Rösler Tyre Innovators GmbH & Co. KG together with three other project partners. The KI-RAM project is funded with a total of 1.7 million euros by the German Federal Ministry of Digital Affairs and Transport as part of the mFUND innovation initiative.

Every year the number of cars on our roads is increasing and with it the need for new and spare tires. In 2022 the number of registered vehicles amounted to 48.5 million (passenger cars) and 3.8 million (passenger cars and semitrailers). According to the Federal Environment Agency, vehicle numbers have increased in all sectors since 2008: Cars by 18%, trucks by 51% and other vehicles by over 22%. For 2022, forecasts predict that 45 million passenger car tires and 2.8 million truck tires will be sold in the spare tire business alone. More tires cause more abrasion, as the rubber of the tires is worn down by contact with the road while driving. In the process, rubber microparticles are rubbed off and end up in the environment. When it rains, these tiny particles are washed off the road and eventually find their way into water and soil. The amount of tire wear depends on a variety of factors, such as the type of road surface, tire pressure, weather as well as driving behavior and speed.

The aim of the project "AI-based solutions to reduce abrasion and traffic-related microplastic emissions" (KI-RAM), funded by the Federal Ministry of Digital Affairs and Transport, is to find new ways to reduce tire abrasion. Abrasion data collected online under real conditions, information on critical factors influencing abrasion and forecasting software tools are to form the starting point for new methods to reduce tire abrasion. The objective is to develop an AI-based software tool that uses a new type of tire wear sensor to collect wear data and link it to road and weather conditions as well as information on driving behavior. In addition, laboratory indicators are collected on the abrasion behavior of the rubber compounds used in the tire. The results should provide further insight into the factors influencing tire wear, as well as predict wear in different situations and compare the wear performance of different types of tires, with the aim of minimizing wear. "Using an AI-based software tool, data generated in field trials is linked with road and weather data from the Federal Ministry of Digital Affairs and Transport. In combination with supplementary data on driving behavior and tire compounds, AI-based predictions on tire wear should become possible," says Paul Rösler, Managing Director of Rösler Tyre Innovators GmbH & Co. KG and joint coordinator for the "KI-RAM" project.

The Fraunhofer IMWS brings its broad expertise in the evaluation and optimization of rubber compounds for tire treads and its knowledge in the field of digitalization and artificial intelligence to the project. The project compares the significance of various laboratory indicators for the abrasion of rubber compounds with the results of field tests on tires. The rubber mixing room with tandem kneading line available to the IMWS at the Fraunhofer PAZ in Schkopau since the end of 2022 will also be used in the process. “For many years, a focus of the materials research activities of the Fraunhofer IMWS has focused on understanding and optimizing the reinforcement, dissipation and abrasion in rubber compounds, as well as on developing imaging methods to describe the dispersion of filler materials on different length scales. The "KI-RAM" project offers us a very good opportunity to contribute and expand our expertise." says Mario Beiner, Group Manager "Polymer-based Material Design" at the Fraunhofer IMWS.

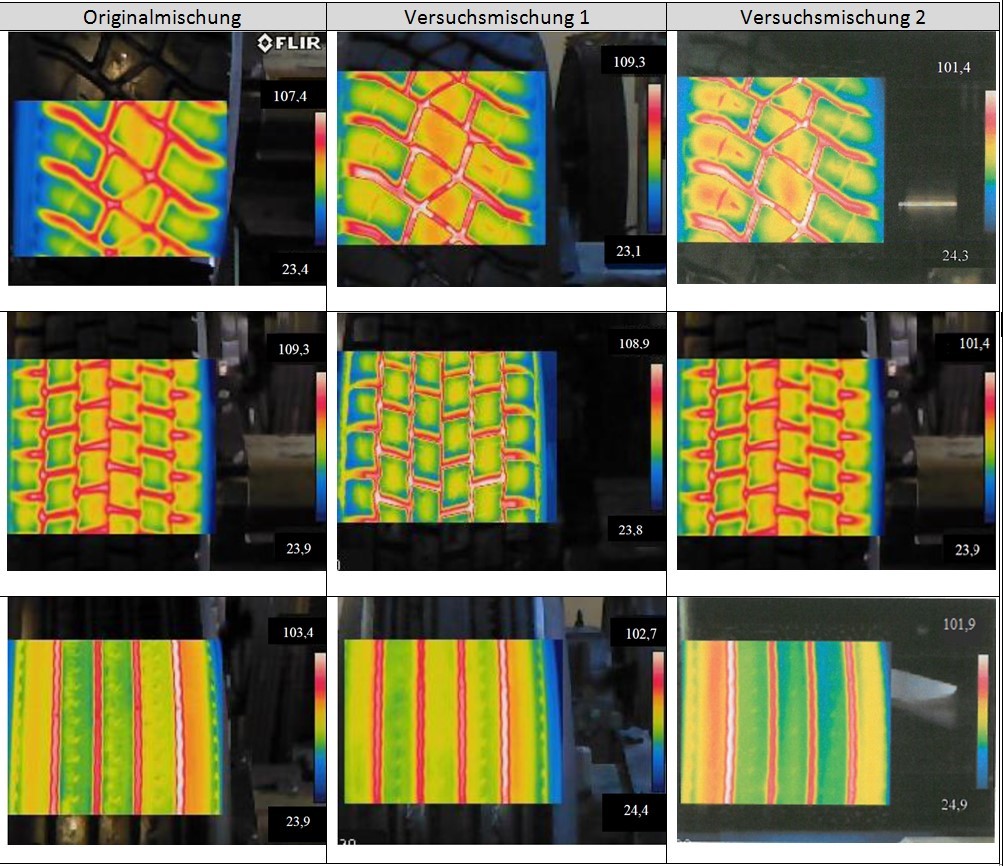

In addition to the Fraunhofer IMWS, project partners include Rösler Tyre Innovators GmbH & Co. KG, iMES Solutions GmbH, DENKweit GmbH and the University of Paderborn. Rösler Tyre Innovators GmbH & Co. KG will provide the project consortium with an inline abrasion sensor for trucks, which records the data on tire abrasion while driving and transmits it to an evaluation device in the vehicle. This sensor is being further developed and optimized in cooperation with the University of Paderborn. In the project, iMES Solutions GmbH focuses on the AI-based analysis of data collected online on tire wear, weather, road surface and driving behavior to determine the main causes of wear. DENKweit GMBH is contributing its expertise in the field of AI-based image evaluation and is concentrating on developing a new measuring method for the evaluation of tire abrasion on the basis of infrared images.

The project was launched at a public kick-off meeting. Representatives of the Federal Ministry of Digital Affairs and Transport, the Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection and the Federal Environment Agency as well as the project sponsor TÜV Rheinland Consulting GmbH attended the meeting. Also present were representatives from the German Tire Trade and Vulcanizing Trade Association (BRV), the German Rubber Industry Association (wdk), the German Rubber Society East (DGK Ost) and the IT Cluster Central Germany. In his welcoming address, Dr Jürgen Ude, State Secretary, State Chancellery and Ministry of Culture of the State of Saxony-Anhalt, Staff Section for Major Investments, Structural Change, underlined the relevance of the research activities for structural change in the central German mining area.

This is a modal window.