The sustainable production of chemical base materials using CO2 as a carbon source is the goal of the "PKat4Chem" project. The project partners involved aim at further developing the process of low-temperature plasma catalysis so that gases produced from biomass can be converted into methanol or ethylene in a single-stage process. The Fraunhofer Institute for Microstructure of Materials and Systems IMWS is contributing its expertise in analyzing the materials used. The approach promises high efficiency and flexibility.

Producing base chemicals without consuming fossil raw materials and thus generating CO2 emissions is one of the most important tasks in achieving climate targets. Such base chemicals, which are produced in enormous quantities, are starting materials for many other industrial and everyday products such as plastics, fertilizers and fuels.

Power-to-X technologies are a very effective approach for the sustainable production of organic base chemicals such as ethylene, methanol or styrene: Here, electricity from renewable energies is used. The hydrogen required for the chemical compounds can also be produced emission-free using electrolysis. If CO2 is used as a carbon source, the carbon cycle can be closed and even greenhouse gases that have already been emitted can be removed from the atmosphere.

The "PKat4Chem" project focuses on the conversion and thus utilization of CO2 for the production of chemical base materials. The consortium is focusing on low-temperature plasma catalysis (LTP catalysis). With this technology, gases produced from biomass such as methane (CH4) in combination with CO2 are to be activated highly efficiently using plasma and converted into chemical base materials such as methanol (CH3OH) or ethylene (C2H4) using appropriate catalysts in a single-stage process.

The project focus is on LTP catalysis reactors because they can achieve very high efficiencies of up to 95%. They also offer the advantage of simple scalability and lower investment and operating costs. This enables a potential turnkey process that can be switched on and off dynamically and in line with demand.

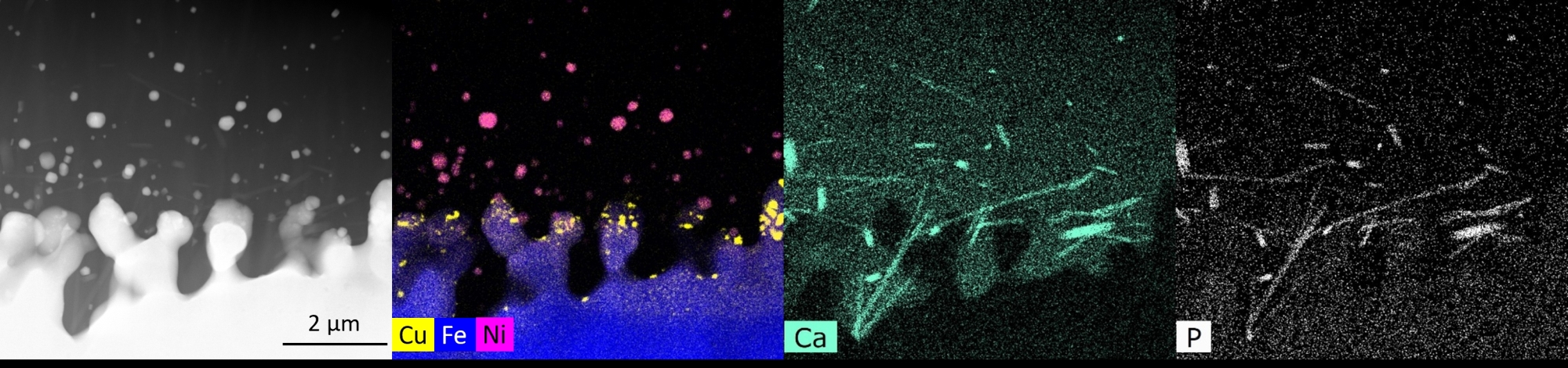

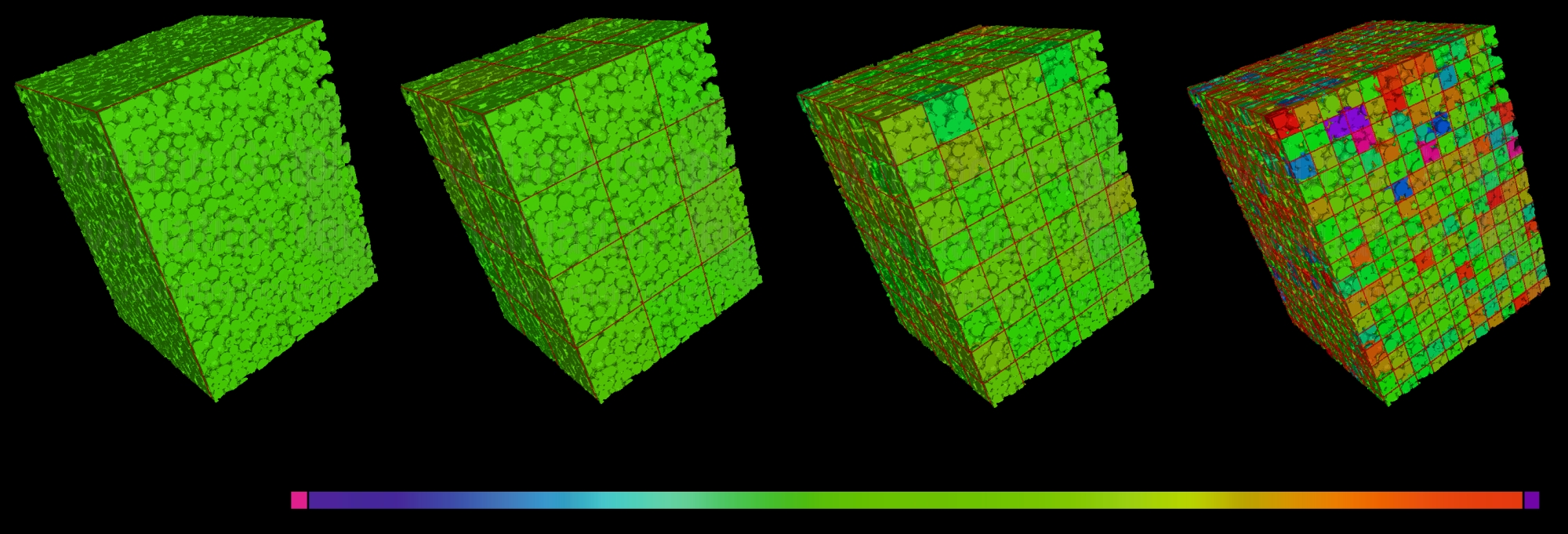

The aim of the project, which will run until the end of 2027, is to develop a new type of process chain. The focus lies on the development of an LTP catalysis reactor module unit for the synthesis of methanol or ethylene. This is to be validated in field trials on a demonstrator at an existing biogas plant. In the project, the Fraunhofer IMWS is responsible for the microstructural characterization of the patented electrode material and the corresponding catalysts. The materials are analyzed with regard to their microstructure using scanning electron microscopy (SEM) and transmission electron microscopy (TEM) and the element distributions are examined using energy dispersive X-ray spectroscopy (EDXS). In addition, the investigation of near-surface material changes due to the effect of the LTP catalysis using X-ray photoelectron spectroscopy (XPS) and time-of-flight secondary ion mass spectrometry (ToF-SIMS) is at the forefront of the Fraunhofer team's investigations.

"In order to understand the processes at the electrode, we also want to investigate fundamental properties using thermal analysis and clarify the redox processes at the various interfaces of the materials involved using electron energy loss spectroscopy (EELS). This would make it possible to develop materials 'under sight'," explains Christian Thieme, who is leading the project at Fraunhofer IMWS. "The approach offers numerous advantages, from high flexibility and decentralized application to the possibility of actually using biogas completely and eliminating process-related CO2 emissions. Last but not least, we are also motivated by the fact that there is a huge demand for sustainable base chemicals, both for the chemical industry and, in the long term, for the transport sector."

In addition to the project coordinator enaDyne GmbH, EDL Anlagenbau Gesellschaft mbH, Arcanum Energy Systems GmbH & Co KG, HTWK Leipzig, TU Bergakademie Freiberg, Leipzig University, Ruhr University Bochum and Fraunhofer IMWS are also involved in the "PKat4Chem" project.

The project is funded as part of the energy research program of the Federal Ministry of Economics and Climate Protection (BMWK) (funding code: 03EE5187F).

(March 11, 2025)