Software supports formulation and processing conditions for tire treads

The Fraunhofer Institute for Microstructure of Materials and Systems IMWS in Halle (Saale) is working with six partners to develop intelligent algorithms and methods that support the production of application-optimized rubber compounds. The goal is software that uses information on formulation and processing conditions to derive predictions and optimization strategies.

![BMBF_CMYK_Gef_M [Konvertiert]](/en/presse/pressemitteilungen/rubber-compounds-formulation-software/jcr:content/fixedContent/pressArticleParsys/textwithinlinedimage/imageComponent2/image.img.jpg/1722864043710/BMBF-gefoerdert-en-NEU.jpg)

Rubber is an important raw material for the production of goods such as car tires or disposable gloves. It is extracted naturally from rubber trees or produced synthetically from monomer building blocks using appropriate polymerization reactions, after which it is enriched with fillers and a variety of additives depending on the required material properties of a product.

Until now, formulation and process development for new rubber compounds has been based primarily on accumulated experience and personal expertise. However, this is problematic with regard to the quality and long-term further development of elastomer products. Together with six partners, the Fraunhofer IMWS is therefore developing a digital tool in the "InSuKa" project that combines formulation, processing and further processing-related databases with innovative forecasting tools based on intelligent algorithms. Users of the solution should receive early indications of suitable recipe adjustments and optimum processing conditions, which can simplify and shorten development and manufacturing processes for rubber products. The rubber industry can benefit from the creation of industry standards for recording process and material data and the development of a powerful prediction tool for process and material optimization.

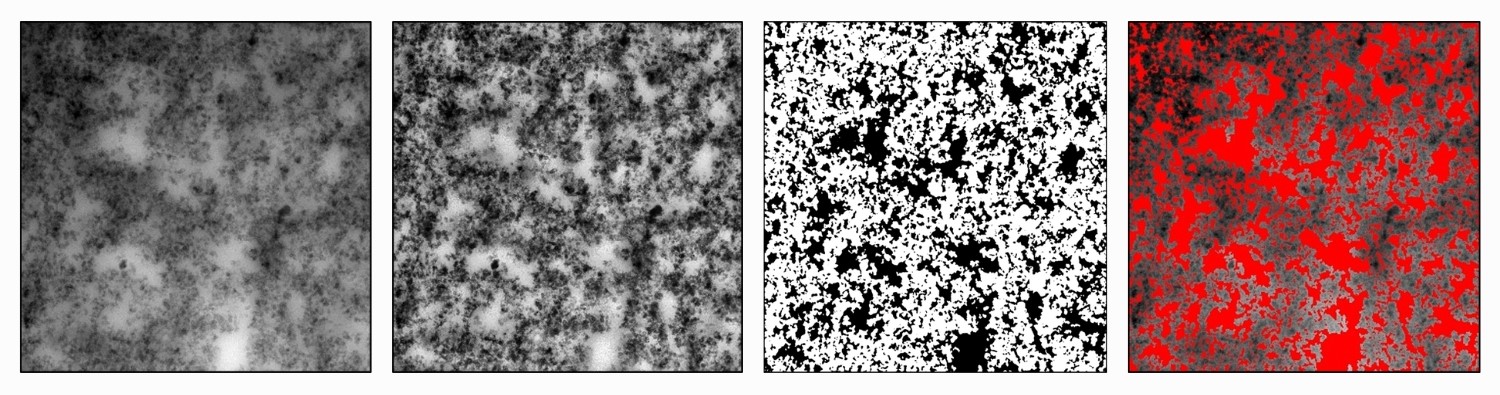

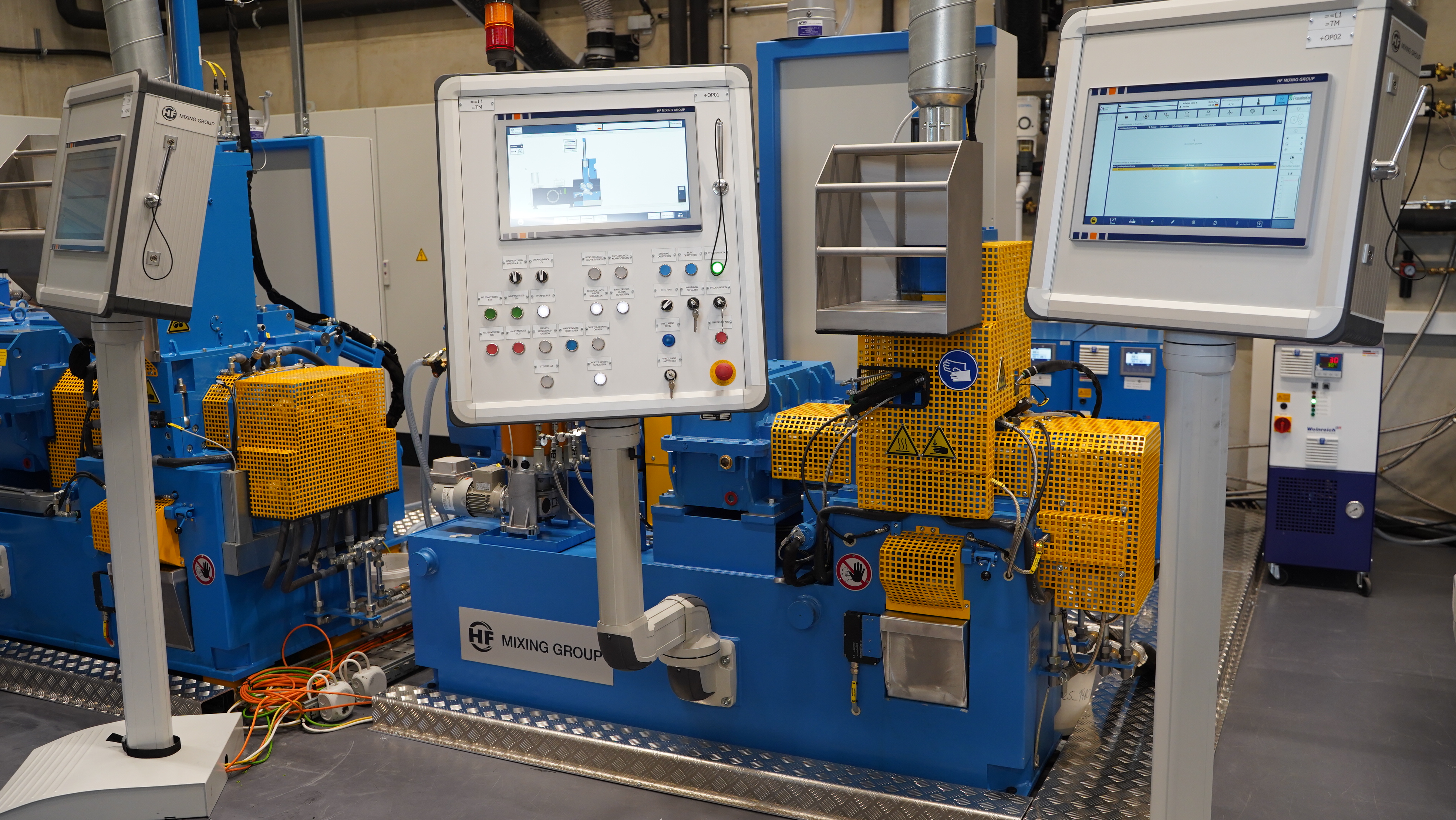

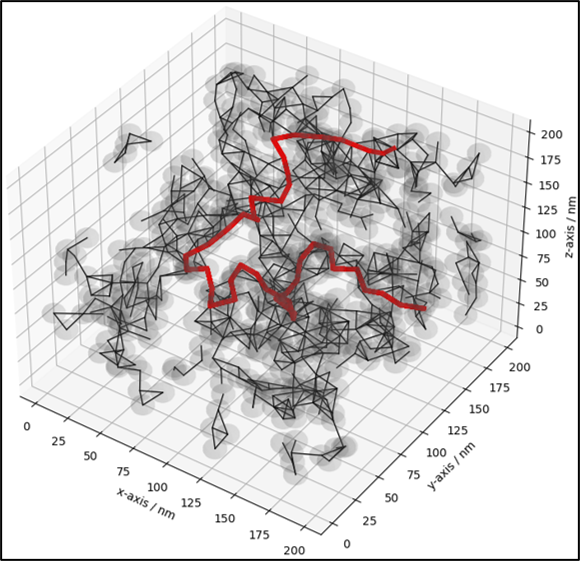

The Fraunhofer IMWS contributes its experience in the evaluation and optimization of rubber compounds and their processing with internal mixers of various sizes (1.5 l and 5 l) in the rubber mixing room at its Schkopau site. Relationships between processing conditions, formulation and final properties are to be uncovered and systematically used to optimize rubber compounds. The activities of the Fraunhofer IMWS focus in particular on new methods for quantifying the multiscale filler dispersion in rubber compounds for tire treads. Imaging methods for recording different length scales and methods based on artificial intelligence (AI) for computer-aided image evaluation are used. The aim is to obtain reliable information on the influence of process and formulation adjustments on the properties of rubber compounds. To this end, processing data recorded inline, new parameters for the quantitative description of the multiscale filler dispersion and information on the rubber compound properties are combined and made available for further AI-based analysis.

"Research into parameters for quantifying multiscale filler dispersion is an important basis for uncovering correlations between the mixing process and filler distribution, but is also significant for understanding the relationship between processing parameters, formulation and application-relevant mechanical properties. The results can be used to significantly improve the efficiency of material and product development in the rubber industry," says Prof. Dr. Mario Beiner, head of the "Microstructure-based Material Design" group at the Fraunhofer IMWS.

The joint project "InSuKa" is funded by the Federal Ministry of Education and Research as part of the MaterialDigital platform and will run until mid-2026.