The role of secondary optics in heat management of white-light LEDs

Optimal heat management is essential for the performance and lifespan of white-light LEDs. The temperature stability of the secondary optics, which ensures even light distribution, is often overlooked; this can lead to a total failure of the optic. The Fraunhofer Application Center for Inorganic Phosphors has used infrared thermography to develop an approach that can be used to analyze heat increases in secondary LED optics. This will minimize failure risks and improve the lifespan of phosphors.

In white-light LEDs, a blue LED chip embedded in a transparent plastic (silicone) – generally using a powder-based, yellow-emitting phosphor – creates white light. In addition to its function as an embedding material for LED chips and phosphors, the plastic also provides an initial opportunity to direct the light. An additional (secondary) optic is then used to control the light more precisely for the specific application.

Heat management of these components plays a decisive role in helping LEDs achieve the optimal light output and desired lifespan. The heat created in the component needs to be dissipated as much as possible, and all of the chosen materials must be able to withstand the operating temperatures. In recent years, great strides have been made in terms of the temperature stability of LED chips as well as their directly connected primary optics, so white-light LEDs can now be used at much higher operating temperatures. However, research by the Fraunhofer Application Center for Inorganic Phosphors in Soest, published in the trade journal “LICHT,” has shown that these higher temperatures can have effects on the secondary optics that are often overlooked during heat management.

This is especially critical when the secondary optic is made of plastic, which is often the case due to its cost and weight advantages over glass optics. The heat deflection temperature for common secondary optic materials such as polymethylmethacrylate (PMMA) and polycarbonate (PC) are 95 °C and 122 °C, respectively. “If the secondary optic is operated above these temperatures for a longer period of time, its optical properties change. In the worst case, they could even deform, which would mean a total functional failure of the optic – even though the temperature limits are still being observed for all the other components,” explains Dr. Peter Nolte, Team Leader for “Reliability of Phosphors” at the Fraunhofer AWZ.

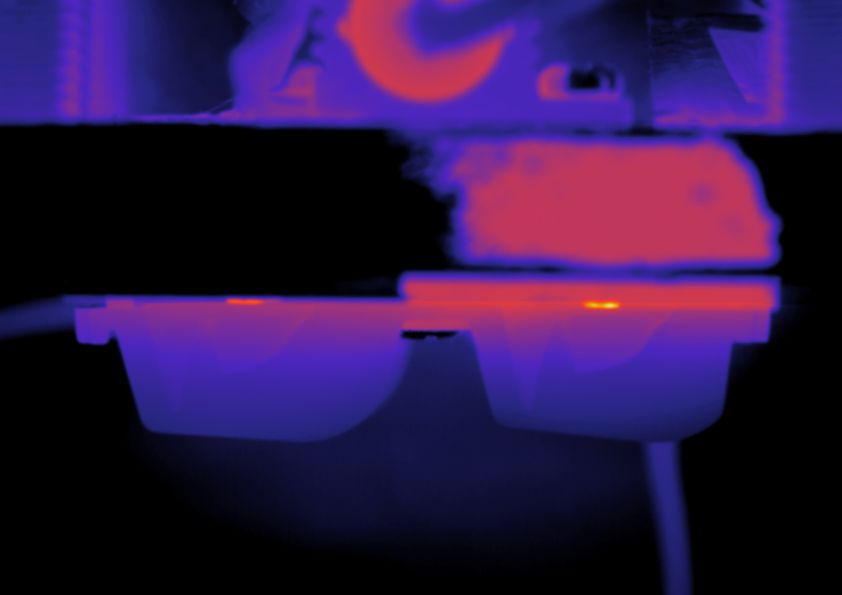

His team has developed a method to measure the exact temperature profile of secondary optics. These optics are analyzed and evaluated at the LED’s maximum permissible output and temperature in combination with a high-output LED module, using a contactless infrared thermography method. Measurements of PMMA and PC materials showed that this procedure is especially useful for precisely determining the temperature of the interior surface. This allows conclusions to be drawn about which materials are suitable for which operating temperatures. Nolte will present his research on September 27, 2018, in a talk at the “LED Professional Symposium” in Bregenz.